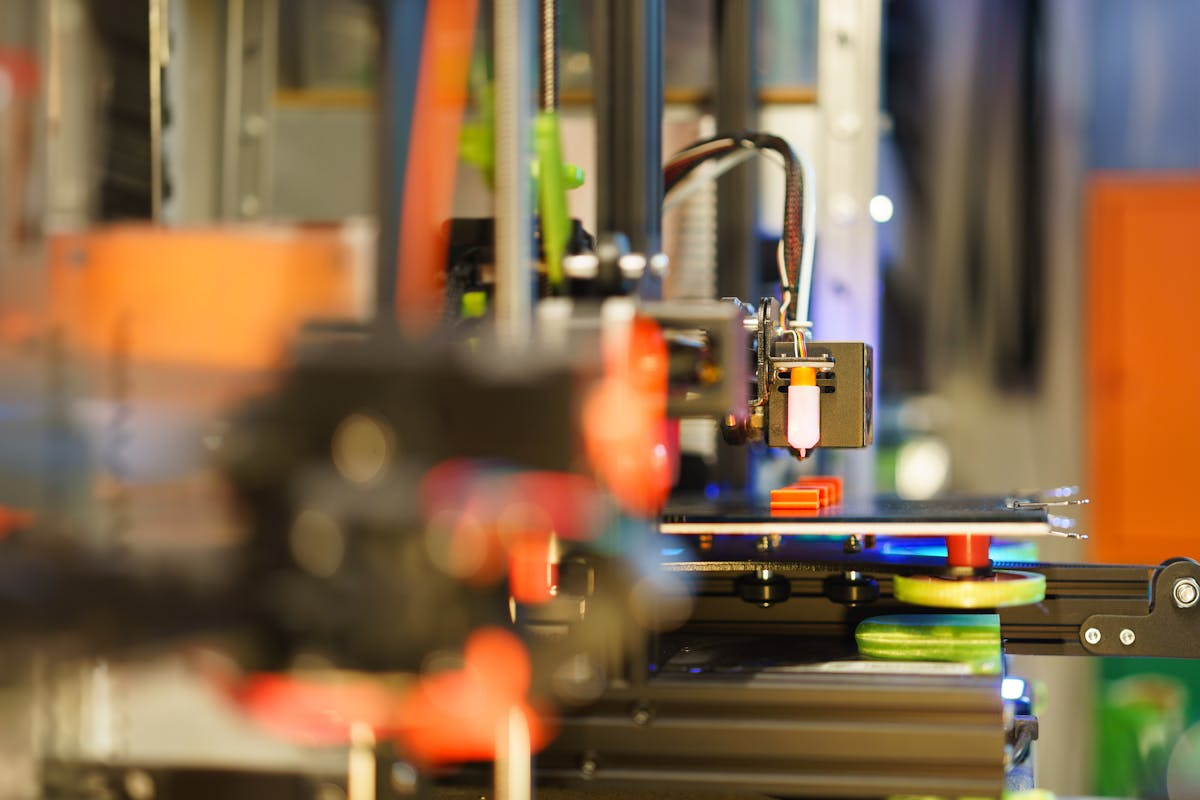

The University of Maine has recently revealed an impressive 3D printer of colossal proportions, capable of constructing an entire house.

The university has declared that it has exceeded its previous achievement by unveiling the world’s largest polymer 3D printer, which is four times larger than its predecessor.

The Factory of the Future 1.0 (FoF 1.0) has the capacity to print objects up to 96ft (29m) long, approximately the size of a blue whale.

However, experts project that despite this progress, the majority of the population will still reside in conventional brick and mortar dwellings.

RELATED : Best performance management systems for small companies

RELATED :Email Marketing Solutions For Small Business: The Best 6

RELATED: When Is the Best Time to Sell Your Structured Settlement Annuity?

RELATED: Space Junk Alert: Japan’s Mission to Clean Up Orbital Debris

RELATED : White House Initiates Early Planning for 6G Development

RELATED : Top 10 Online HR Software for Small Businesses

RELATED : 9 Top Help Desk Apps for Maximum Productivity

RELATED : Pioneering Technology: Exploring the Rich History of Computers

ALSO READ: Is Santa Barbara the Right Car Accident Lawyer for You?

ALSO READ :Uncovering the Top Birth Injury Lawyers in New York

According to Dr. Eujin Pei from Brunel University, large 3D printers, like the one unveiled in Maine, are more likely to be employed in producing parts of houses rather than entire residential structures.

Dr. Pei emphasizes the importance of these printers in historical restoration, highlighting their ability to create decorative elements or restore damaged parts.

He also mentions the potential application of these printers in post-disaster scenarios for manufacturing components of buildings that have been destroyed.

Maine University aims to utilize the printer for generating affordable housing, as well as for constructing bridges, boats, and wind turbines, with the capability to print up to 500lbs (227kg) of material per hour.

In an effort to promote sustainability, the university is striving to diversify the materials used in 3D printing beyond plastic. The goal is to prioritize recycled polymers and explore more environmentally friendly options, such as utilizing residual wood from sawmills found in Maine.

Dr. Pei acknowledges that wood may not possess the same level of durability as other materials, but its eco-friendliness makes it a viable choice.

While the 3D printing process already minimizes waste and saves time by utilizing only necessary materials, there are still environmental impacts to consider.

Dr. Pei points out that certain materials used in production cannot be fully recycled due to contamination.

However, by designing products digitally, their energy efficiency can be calculated in advance, allowing for a printing process that is both time-efficient and resource-saving.

Dr. Pei emphasizes that this approach offers significant cost savings in terms of energy and resource efficiency.

RELATED : Best performance management systems for small companies

RELATED :Email Marketing Solutions For Small Business: The Best 6

RELATED: When Is the Best Time to Sell Your Structured Settlement Annuity?

RELATED: Space Junk Alert: Japan’s Mission to Clean Up Orbital Debris

RELATED : White House Initiates Early Planning for 6G Development

RELATED : Top 10 Online HR Software for Small Businesses

RELATED : 9 Top Help Desk Apps for Maximum Productivity

ALSO READ: Is Santa Barbara the Right Car Accident Lawyer for You?

ALSO READ :Uncovering the Top Birth Injury Lawyers in New York

The Advanced Structures and Composites Center at the university, led by Habib Dagher, has developed a massive printer in Maine that is partially funded by the US military.

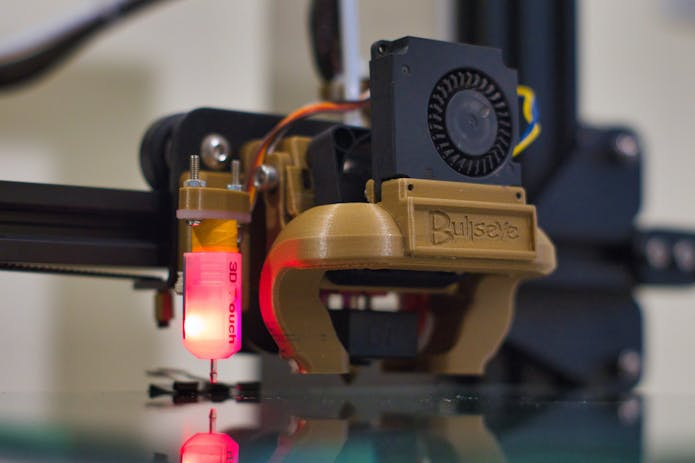

This printer utilizes advanced technologies such as sensors, high-performance computing, and artificial intelligence to manufacture large products.

The previous version of this printer, FoF 1.0, successfully built a prototype bungalow.

However, the main objective of the new FoF 1.0 is to address Maine’s housing shortage. Interestingly, wood is used as the primary material in the manufacturing process.

Moreover, the university highlights that these two printers can collaborate in producing the same object.

The potential of 3D printing to revolutionize manufacturing, both on a large and small scale, has long been anticipated.

The applications of this technology have spanned across various industries, including aerospace, biotechnology, and even entertainment.

However, it is important to acknowledge the negative implications as well. Criminals have exploited this technology to produce illicit weapons.

In a significant case in the UK, two individuals were imprisoned for manufacturing sub-machine guns using a 3D printer.

Similarly, in 2023, a man from Birmingham received a five-year prison sentence for producing 3D-printed assault rifles.

RELATED : Best performance management systems for small companies

RELATED :Email Marketing Solutions For Small Business: The Best 6

RELATED: When Is the Best Time to Sell Your Structured Settlement Annuity?

RELATED: Space Junk Alert: Japan’s Mission to Clean Up Orbital Debris

RELATED : White House Initiates Early Planning for 6G Development

RELATED : Top 10 Online HR Software for Small Businesses

RELATED : 9 Top Help Desk Apps for Maximum Productivity

ALSO READ: Is Santa Barbara the Right Car Accident Lawyer for You?

ALSO READ :Uncovering the Top Birth Injury Lawyers in New York

The activation of the world’s largest 3D printer marks the beginning of a new era in large-scale additive manufacturing.

This immense industrial-grade machine, with the ability to print objects up to 100 feet in length, is set to revolutionize various industries, including construction and aerospace.

What was once considered a mere concept in science fiction has now become a tangible reality.

This colossal printer, comparable in size to a multi-story building, has the capability to create entire structures, components, and prototypes with unparalleled speed and precision.

The reliance on traditional manufacturing methods is now a thing of the past, as this remarkable technological advancement opens up endless possibilities for designers, engineers, and innovators.

RELATED : Best performance management systems for small companies

RELATED :Email Marketing Solutions For Small Business: The Best 6

RELATED: When Is the Best Time to Sell Your Structured Settlement Annuity?

RELATED: Space Junk Alert: Japan’s Mission to Clean Up Orbital Debris

RELATED : White House Initiates Early Planning for 6G Development

RELATED : Top 10 Online HR Software for Small Businesses

RELATED : 9 Top Help Desk Apps for Maximum Productivity

ALSO READ: Is Santa Barbara the Right Car Accident Lawyer for You?

ALSO READ :Uncovering the Top Birth Injury Lawyers in New York

Main Purpose of The World’s Largest 3D Printer

The opportunities are vast. Envision the possibility of 3D printing complete sections of a bridge or the body of an aircraft.

This technology holds the potential to streamline manufacturing processes, minimize inefficiencies, and allow for the development of intricate, personalized products that were once beyond reach.

With this groundbreaking printer in operation, it is clear that the future of manufacturing is now.

Race yourself to witness the onset of a new industrial revolution, where the limits of what is achievable are constantly being pushed forward by the sheer power of additive manufacturing.